The rapid growth of energy storage systems (ESS) is reshaping global power infrastructure, but it brings new challenges for safety and reliability. As more lithium-ion batteries are deployed, the risk of thermal runaway, fire, and explosion events increases. CLOU's new Active Ventilation Explosion-Proof System, outlined in a recent white papersize 3MB, PDF download in new tab by Dr. Wang Fuqing, sets a new benchmark for fire safety in energy storage stations.

The Safety Imperative in Modern Energy Storage

As energy storage installations soar—projected to reach 220 GW/972 GWh annually by 2035—so do safety incidents. Over the past decade, fire and explosion events have occurred worldwide, often with severe consequences. Recent incidents in China, South Korea, the USA, Japan, Germany, and the UK highlight common causes: short circuits, design flaws, poor maintenance, and inadequate fire or gas management. These events underline the need for robust, multi-layered safety systems that can prevent, detect, and contain hazards before they escalate.

North America's regulatory framework, led by the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL), is the most comprehensive globally. Standards such as NFPA 68, NFPA 69, NFPA 855, and UL 9540A set strict requirements for explosion venting, fire suppression, and system testing. The Canadian CSA/ANSI C800 standard further supports large-scale fire testing and quality assurance.

CLOU's Multi-Tiered Safety Architecture

CLOU's approach is built on three pillars: early detection, effective fire suppression, and explosion prevention. The system uses real-time monitoring at both the module and container level. The Battery Management System (BMS) tracks cell temperature and voltage, triggering alarms and disconnecting circuits if thresholds are exceeded. Container-level sensors monitor for combustible gases (such as hydrogen and carbon monoxide), smoke, and temperature. If flammable gases are detected, the active ventilation system starts automatically, reducing concentrations and preventing explosive conditions.

Traditional fire suppression methods, like total flooding with gaseous agents, have limitations in containerised ESS. They rely on airtight enclosures and can allow reignition or gas accumulation, raising the risk of explosion. CLOU instead uses a water spray system, which rapidly cools overheated cells and flames. This system works in tandem with active ventilation, continuously expelling flammable gases during a fire event. The result is a comprehensive "extinguishment–cooling–explosion containment" mechanism.

Explosion Prevention and Venting

CLOU's system addresses explosion risk in two ways: preemptive control and structural venting. Gas detectors trigger ventilation when concentrations reach 10% of the Lower Explosive Limit (LEL), keeping levels safely below 25% LEL as required by NFPA 69. If an explosion does occur, preset relief structures—such as burst panels or louvers—vent pressure and flames upward, protecting both the container and adjacent equipment.

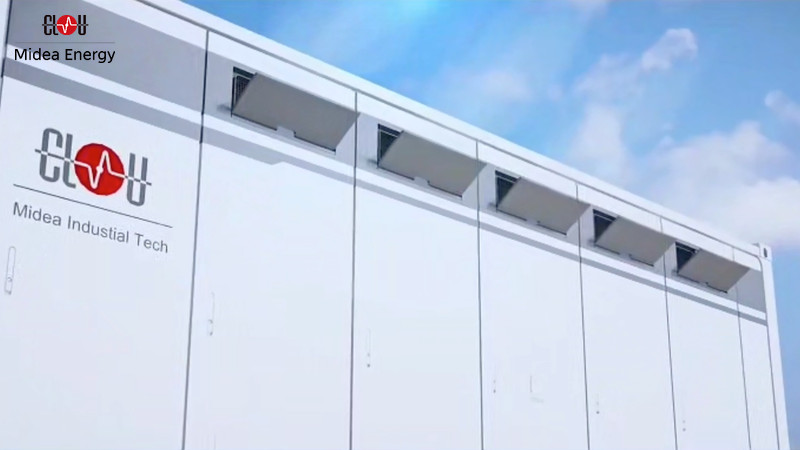

The active ventilation system features five natural exhaust louvers at the top and two air intakes at the bottom. Even if only one intake is operational, simulation tests confirm that flammable gas concentrations remain below critical limits. If power is lost, the system switches to natural ventilation, ensuring continuous protection. Louvers are angled to direct flames vertically, preventing lateral spread and cross-container thermal runaway.

Large-Scale Fire Test: Real-World Validation

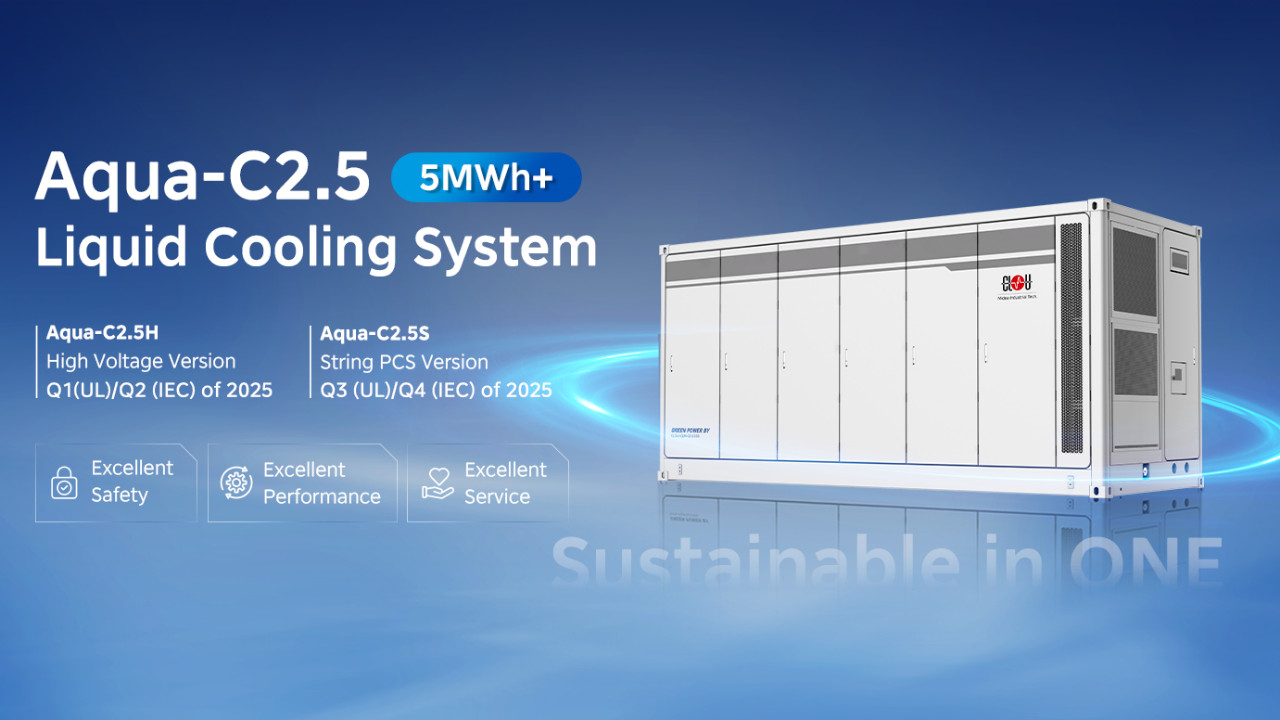

CLOU's ThermoFlux Active Ventilation Explosion-Proof System was tested at a CSA-accredited facilit CLOU's Aqua-C2.5 Energy Storage System Passes Rigorous CSA TS-800 Fire Safety Testy using four Aqua C2.5 liquid-cooled BESS containers in a 20 MWh configuration. In the test, one container was ignited and burned for over 59 hours, reaching internal temperatures above 1300°C. Adjacent containers remained structurally intact, with battery module temperatures well below thermal runaway thresholds. Flames and gases were vented upward, and no lateral propagation occurred. The test confirmed the system's ability to contain fire and explosion hazards, even in high-density deployments.

CLOU's Aqua-C2.5 Energy Storage System Passes Rigorous CSA TS-800 Fire Safety Testy using four Aqua C2.5 liquid-cooled BESS containers in a 20 MWh configuration. In the test, one container was ignited and burned for over 59 hours, reaching internal temperatures above 1300°C. Adjacent containers remained structurally intact, with battery module temperatures well below thermal runaway thresholds. Flames and gases were vented upward, and no lateral propagation occurred. The test confirmed the system's ability to contain fire and explosion hazards, even in high-density deployments.

Takeaway

CLOU's Active Ventilation Explosion-Proof System sets a new standard for ESS fire safety. By combining early detection, water-based suppression, and engineered explosion venting, CLOU delivers robust, reliable protection for energy storage stations. The system's performance in large-scale fire testing demonstrates its value for gigawatt-scale deployments, supporting safe, sustainable growth of renewable energy infrastructure.

Ready to power up your projects with the safest, most reliable energy storage on the market? Discover how CLOU's Active Ventilation Explosion-Proof System can protect your assets and support your renewable ambitions—no compromises, just confidence. Contact us Contact Us today to take your energy storage to the next level!

Contact Us today to take your energy storage to the next level!

All comments are moderated before being published. Inappropriate or off-topic comments may not be approved.