Evolving Power Markets for the Renewable Age

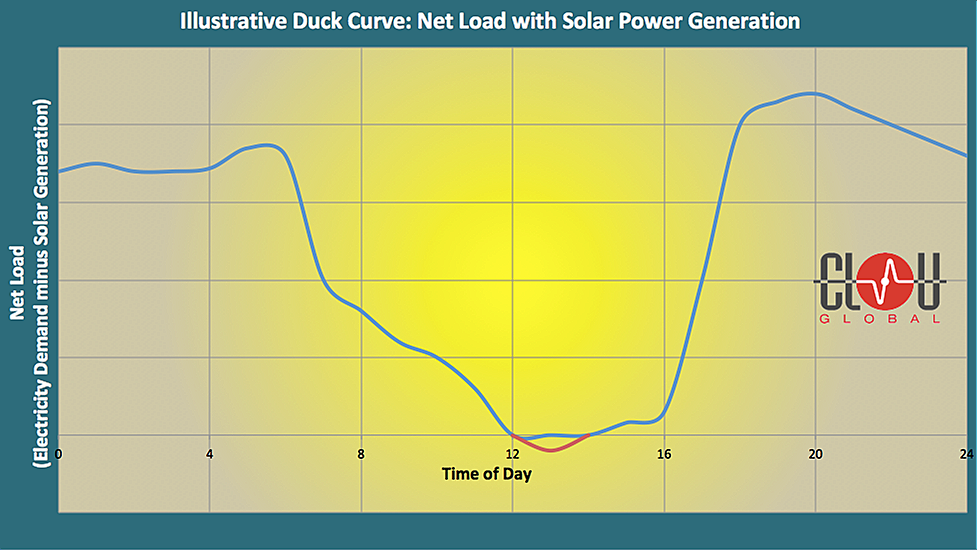

The way we make and use power is changing fast as countries switch to cleaner energy sources. This is driven by things like renewables getting cheaper, governments wanting fewer greenhouse gases, and companies setting green goals. At the heart of this clean energy shift are power markets. They need to evolve so they can handle …

Continue reading "Evolving Power Markets for the Renewable Age"