Energy metering has never been done for fun. There is money involved, so the meter accuracy has to be verified.

In the past without any electronics it was really challenging. You needed a voltage/current source with a high stability, calibrated wattmeters and a calibrated stop-watch.

The source was transformer operated with regulators for current, voltage and phase shift.

First you adjust voltage and current. Then you read the power from the wattmeters.

The meters connected to the test bench had to be tested one by one.

Each meter has a meter constant, indicating the no. of revolutions per kWh.

Imagine a single-phase meter with a constant of 75 r/kWh. We have adjusted the voltage to 230 V and the current to 10 A. Power factor is 1.

We see on the wattmeter a power of 2300 W.

Now we can calculate the theoretical time for one rotation based on the meter constant.

\displaystyle theoretical\ time = \frac{1000 \cdot 3600}{P \cdot c}P = power

c = meter constant

The theoretical time for one rotation under a power of 2300 W is 20,87 s. (Note that we had no calculator, in best case we calculated with a slide rule.)

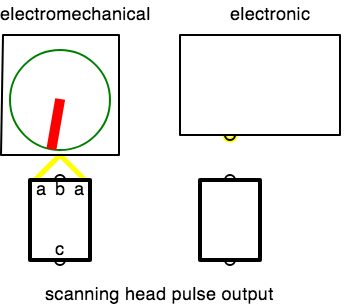

Next step: We stop the time for one rotation. The rotating disk of the electromechanical meter has a coloured mark. Once the mark is in front of the meter you start the watch and you stop it once the mark reaches the same position after one revolution.

Let's say, you stop a time of 21.1 seconds.

Now we use the common formula for percentage error:

\displaystyle percentage\ error = \frac{experimental\ value – theoretical\ value}{theoretical\ value} \cdot 100%So we come to an error of +1.1% . The meter is faster than it should be. At that time the meters had typically an accuracy class 2, so it's PASS.

As you can see there are a lot of influence factors which can spoil the measurement result like

- inaccurate reading from the wattmeter

- source instability (wattmeter needle is moving during the test)

- inaccurate reading from the stop-watch

- too late or too early stopping of the time

- rounding errors in the calculations

Especially the stopping time made the life for the meter testers very hard. So the trick was to stop the time for several revolutions to minimise the human error for start/stop.

If you have portable equipment with a start/stop switch you can compare the error results vs. using a scanning head How does a scanning head work?.

How does a scanning head work?.

Small exercise

In the animation below we see the rotating disk of a single-phase meter (top view without meter case ). This meter has a constant of 100 r/kWh. It's running with a load of 3,450 W.

You have already calculated the theoretical run time per revolution (10.43 s).

Use your satellite synchronised smart phone stop watch to check the meter error.

Leave me a comment with your result :)

In one of the next blogs Principle for Accuracy Testing of Energy Meters we'll see how much easier and faster a meter test is with modern meter test equipment

Principle for Accuracy Testing of Energy Meters we'll see how much easier and faster a meter test is with modern meter test equipment Introducing Our High-Quality Meter Test Equipment for Precise Measurements and testing software

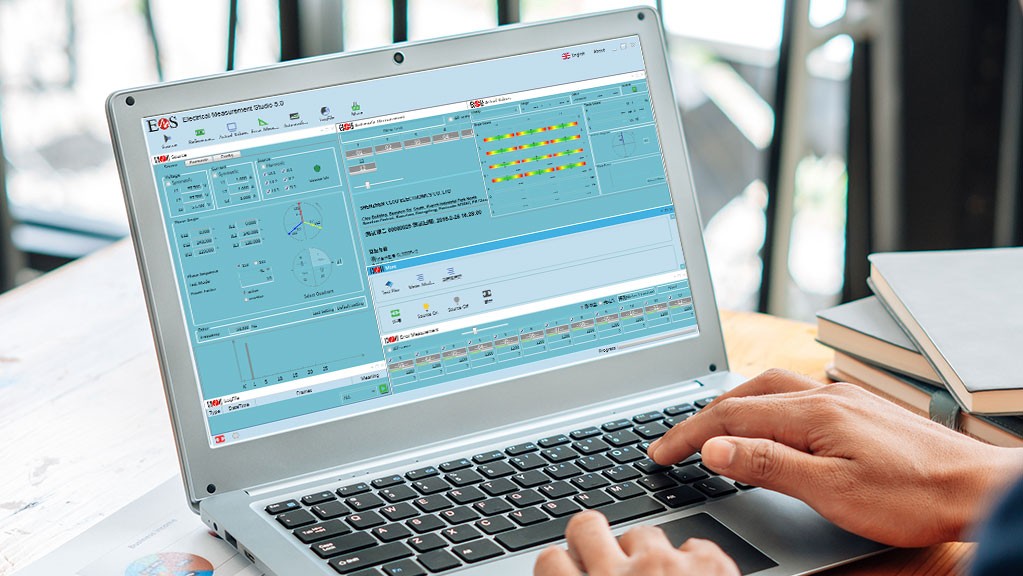

Introducing Our High-Quality Meter Test Equipment for Precise Measurements and testing software Electrical Measurement Studio EMS5. The basics still remain the same.

Electrical Measurement Studio EMS5. The basics still remain the same.

Thank you for reading.

Editor's note: This article was originally published in December 2019 and has been updated for comprehensiveness.

How does the accuracy formula account for different measurment ranges? For example, if a meter is capable of metering up to 5000A, is it to be held to the same accuracy as a meter that is capable of metering 200A?

Thank you for your question!

The error calculation formula remains consistent across different measurement ranges. When discussing meters capable of handling currents of 200 A and 5000 A, it's important to note that these meters are typically connected via instrument transformers (CTs). The secondary side of a CT, at full load, generally provides a current of 5 A (1 A and 10 A are sometimes also in use). The primary side's higher current is determined by the CT ratio.

For accuracy measurements, these meters are tested according to the IEC 62053-22 standard. However, to account for the entire installation, including the CT, you must consider the CT's error as well. Therefore, we recommend conducting laboratory accuracy tests for the meter and also performing on-site tests to ensure overall system accuracy.

How we calculate the Power error in single phase Digital energy meter who calibrate in 240v and 10Amp with 0.5 lag.

Calibration for power is rare. Typically, energy meters are calibrated for energy. The evaluation result will be the same, only that energy calibration is much faster. The procedure for power calibration on a test bench: You read the energy register of the meter. Then you start a register test for 1 kWh. You stop the duration time and after the register test is finished, you read the energy register again. Then you divide the difference by the time. You divide the recorded energy of the test bench reference standard by the same time… and latest now you discover, that energy- and power error must be the same :).

You can find the error calculation formula here.

What should be the accuracy of test bench to test a 0.2S class kwh energy meter?

Thank you for the question. The IEC doesn't give precise information. It only claims that the test equipment must be higher accurate than the meters under test. Best praxis in accordance with the National Metrology Institute of Germany (PTB) is to have a 5 to 10 times better accuracy for the test bench. Since you have a class 0.2S meter, we recommend using a test bench with a 200 ppm reference standard (class 0.02).

What a wonderful exercise ! Different people have different results while we several guys did one rotation at the same time—-that can be called human error. The results, one is 1.7%, another is 4%. Time is important! We did faster, the data is more accurate. That is why we need a sophisicated electrinic measuring machine—to aviod human error.

Thank you for participating. You understand the principle.

My question is this, we installed a single phase meter but doesn't gives out electric supply.(out put)

Most likely the internal relay is still open.

it is 9.01% , i measured time with stop watch – 11.37 Sec.

Thank you for participating. Try the same exercise with more rotations.

Thank you very much for explaining about KWH meter accuracy check. I understand well.

Thank you for kind comment.

Taking average of 10 stop watch reading – accuracy came out to be -0.47%

Nice result. You understood the principle. Measurement over a longer time (more revolutions) is better to minimize the measurement uncertainty.

Thank you for participating.

How would you test a 3 phase meter accuracy if there was a 3 phase load to test. I usually test one phase at a time but now we have a 3 phase load. Would you have a calculation for this?

The principle is exactly the same. You take the meter constant (c) of the three-phase meter. It's given on the name plate. Then you take the sum power of all three phases (P) and calculate the theoretical run-time. By stopping the real run-time you can calculate the meter error.

It's more difficult to control the power of the three phases, so maybe you consider sourcing a portable testing device. This device makes the error measurement based on the actual power automatically. Still, it's possible to do it manually.

I calculated +2.7%, right?

Nice result. Thanks for participating.

Sir I have small confuse.why are multiplying 1000

The power is given in W (watt). The time is calculated based on the meter constant given in imp / kWh. It's simple math. You can also divide the power with 1000 to get kW.

I'm using my phone to read this page. How can I use the stop-watch? I need to watch the animation to figure out the meter error.

Oh, big problem. Maybe you can use your smart-watch or you borrow a phone from your friend :)