Energy meters Discover the Power of Electronic Energy Meters with Our Expertise are calibrated according to their accuracy class. We cover here the electronic meters according to IEC (International Electrotechnical Commission) and MID (Measuring Instruments Directive) classes only. The actual available accuracy classes are for active energy:

Discover the Power of Electronic Energy Meters with Our Expertise are calibrated according to their accuracy class. We cover here the electronic meters according to IEC (International Electrotechnical Commission) and MID (Measuring Instruments Directive) classes only. The actual available accuracy classes are for active energy:

- Class 2 (IEC 62053-21) equivalent to class A (MID EN 50470-3)

- Class 1 (IEC 62053-21) equivalent to class B (MID EN 50470-3)

- Class 0.5 S (IEC 62052-22) equivalent to class C (MID EN 50470-3)

- Class 0.2 S (IEC 62052-22)

For reactive energy:

- Class 3 (IEC 62053-23)

- Class 2 (IEC 62053-23)

- Class 1 (IEC 62053-24)

- Class 1 S (IEC 62053-24)

- Class 0.5 S (IEC 62053-24)

The higher accurate reactive classes IEC 62053-24 have been introduced around the year 2016. There is a certain need to capture the reactive energy component more accurate since the large scale energy generation from renewables.

Why do some accuracy classes carry the letter "S" ?

The letter "S" indicates, that the meter is connected by instrument transformers. You can find this class for all CT- and CT/PT meters. So, for example, you can have a meter with a reactive accuracy class 1 (direct connected) or class 1 S (transformer operated).

Why are the MID accuracy classes missing for reactive energy?

The MID does only specify active accuracy classes. So, even when you have an MID compliant meter, the reactive accuracy class is indicated as a number.

How to maintain the meter accuracy?

All energy meters are calibrated The difference between adjustment and calibration individually at the end of the production line under various load conditions. Since we have more than 50 production test benches, we have to take care that each equipment delivers similar test results. There are various internal verification procedures like quality control with dedicated equipment, but I don't want to bore you with details.

The difference between adjustment and calibration individually at the end of the production line under various load conditions. Since we have more than 50 production test benches, we have to take care that each equipment delivers similar test results. There are various internal verification procedures like quality control with dedicated equipment, but I don't want to bore you with details.

Each test equipment has a reference standard Class 0.05 Three Phase Multifunctional Standard CL3115C. This device is the heart for measurement accuracy. The reference standard needs to be higher accurate than the meter under test. There are no rules, how much higher, but we follow the recommendations of the PTB (Physikalisch-Technische Bundesanstalt, Germany). The equipment should be 5 to 10 times higher accurate than the unit under test.

Class 0.05 Three Phase Multifunctional Standard CL3115C. This device is the heart for measurement accuracy. The reference standard needs to be higher accurate than the meter under test. There are no rules, how much higher, but we follow the recommendations of the PTB (Physikalisch-Technische Bundesanstalt, Germany). The equipment should be 5 to 10 times higher accurate than the unit under test.

So, for a class 1 meter, an accuracy of 0.1% would be sufficient. Typically, the reference standards in meter test equipments are operating with accuracy classes of 0.05% or 0.02%.

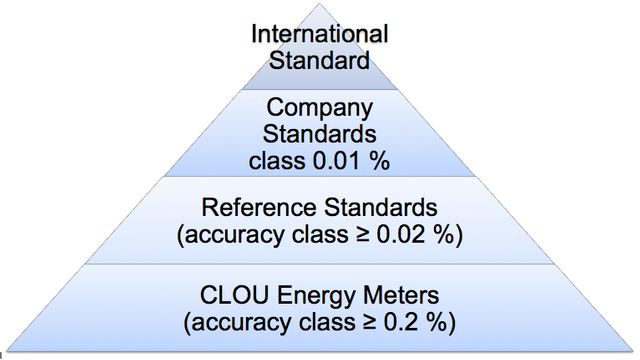

These standards are calibrated periodically (every 3 months) versus our company standards. We have in total 5 devices with accuracy class 0.01%. This high accurate standards are calibrated every 3 months in the National Metrological Institute.

The external calibration needs some time plus transport, but with this process we have always at least two calibrated high accurate standards in our company available.

With this procedure, our end products are traceable to international standards.

Why has a National Metrological Institute the International Standard Attribute?

Our National Metrological Institute (NIM Beijing) has a 10 ppm energy calibration standard. Worldwide, you can find only six of those devices. The initial technology comes from the German PTB. Here it's only necessary to compare voltage, current and time with other institutes. All other National Institutes are using energy transfer standards for an inter-comparison with other countries.

These inter-comparisons are mandatory for all National Metrological Institutes.

Note: This article is extremely simplified. If you have a specific question, we are very glad to answer. Please use the comment function.

Thank you for reading and stay safe.

Editor's note: This article was originally published in July 2022 and has been updated for comprehensiveness.

How long does it usually take to make calibration for reference standards in 3rd party labs?

It depends on the laboratory workload. The calibration process takes two to three days, but you need to join the queue. Including shipment, we are calculating here with 2 months in average when we sent out our standards for recalibration. If you need to avoid downtime for your production or testing, it's recommended to have at least two company reference standards.