Electrical measurement devices, such as multi-meters and on-site calibrators, are essential tools for measuring and analysing customer installations. However, these devices can be subject to a variety of errors that can affect the accuracy and reliability of their measurements. In this article, we will explore some of the possible errors that can occur with electrical measurement devices and discuss ways to minimize their impact.

Reading Errors

One of the most common errors with electrical measurement devices is reading errors, which occur when the device displays an incorrect measurement value. These errors can be caused by a variety of factors, including operator error, instrument calibration issues, measurement range errors and display resolution.

To minimize reading errors, it's essential to ensure that the instrument is calibrated correctly and that the operator is trained to use the device properly.

Range Errors

Range errors occur when the device is set to an incorrect range for the measurement being taken. For example, if a calibrator is set to measure 240 V and the signal being measured is only 30 V, the measurement will be inaccurate. Range errors can also occur if the measurement device's input impedance is too low or too high for the signal being measured.

To avoid range errors, it's important to select the correct range for the signal being measured or auto-range. Auto-range is preferable, except you make error measurements on sites with heavily fluctuating loads. Due to the range switching, you'll lose accuracy. Do measurements under these conditions always with the maximum range.

Zero Errors

Zero errors occur when the device reads a non-zero value when there is no input signal or when the device is set to its lowest range. These errors can be caused by instrument ageing, environmental factors such as temperature and humidity, or mechanical damage.

To minimize zero errors, it's essential to perform regular calibration on the measurement device and to avoid exposing the device to harsh environmental conditions.

Systematic Errors

Systematic errors occur when there are flaws or limitations in the design of the measurement device or the measurement system itself. These errors can affect all measurements taken with the device and may be difficult to correct.

To avoid systematic errors, it's important to select a measurement device that is appropriate for the intended application and to ensure that the measurement system is designed and constructed to meet the required specifications.

To exclude systematic errors, CLOU meter test equipment undergoes regular checks with 3rd party equipment.

Random Errors

Random errors occur due to random fluctuations in the signal being measured or due to external environmental factors. These errors can be unpredictable and can be reduced by taking multiple measurements and averaging the results.

To minimize random errors, it's important to take multiple measurements and to use statistical methods to analyse the results. That's one of the reasons for introducing the repeatability test in the IEC 62052-11:2020.

Hysteresis Errors

Hysteresis errors occur when the measurement device does not respond in the same way to increasing and decreasing input signals. This can cause errors in measurements when the signal is changing rapidly.

To minimize hysteresis errors, it's important to select a measurement device that has a fast response time and to avoid measuring signals that are changing too rapidly for the device to respond accurately. All CLOU test devices are operating on a high sampling rate, so this error can be excluded. You can see the effect nice on old analogue measurement instruments.

Interference Errors

Interference errors occur when external electrical or magnetic fields interfere with the signal being measured. These errors can be minimized by shielding the measurement device and ensuring that it is properly grounded.

To avoid interference errors, it's important to select a measurement device with appropriate shielding and to ensure that the measurement system is properly grounded.

For CLOU devices, the shielding is compliant to the relevant standards (IEC 62057-1 and IEC 60736). If the equipment has a ground-terminal, you should use it.

Temperature Drift Errors

Temperature changes can affect the accuracy of the measurement device, especially when it comes to components like resistors and capacitors. To minimize temperature drift, it's important to select a measurement device that is designed to withstand temperature changes or to use temperature compensation techniques.

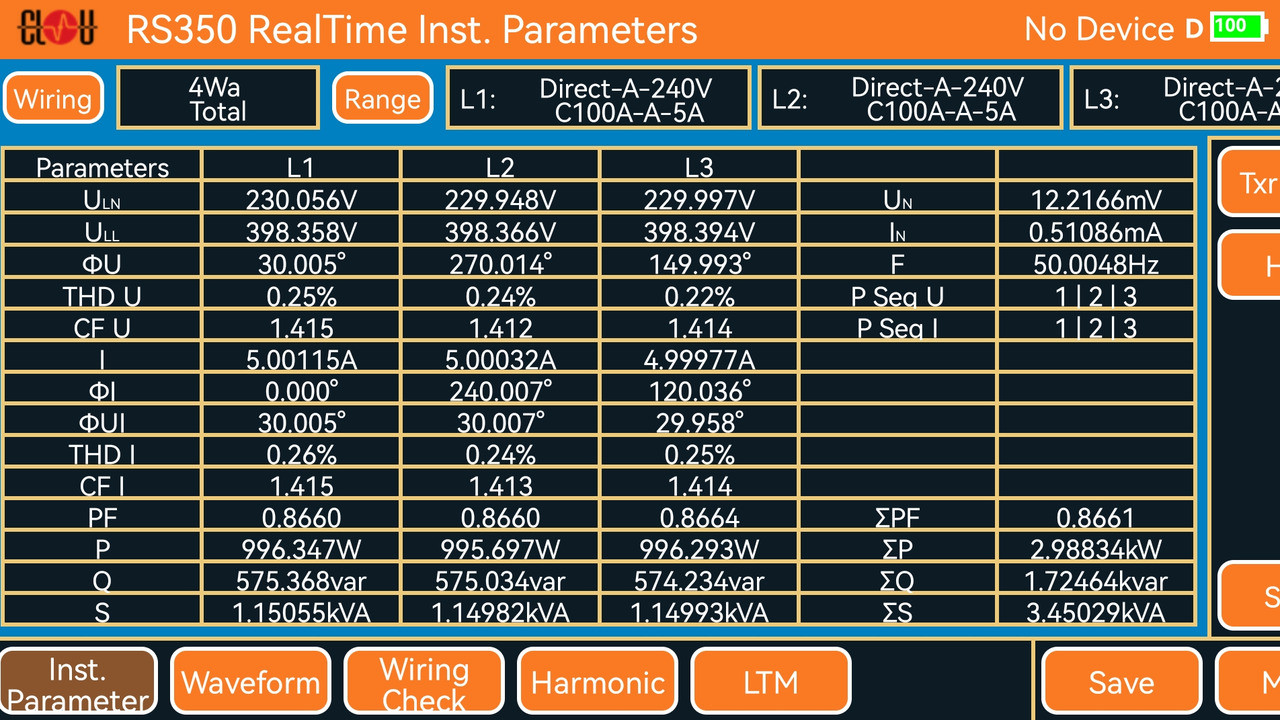

For laboratory use we recommend keeping the environmental temperature on 23 °C ± 2 °C. For outdoor use, stay within the specified temperature range and make sure that the testing device is at least 5 times more accurate than the meter. E.g. testing a energy meter class 1 with clamp-on CTs and a calibrator RS350 is fine. For CT and CT/PT meters, you should consider the direct connection.

Annual Drift Errors

Annual drift errors occur when the measurement device's calibration changes over time. This can be caused by factors such as ageing of components, or mechanical wear and tear.

To minimize drift errors, it's important to perform regular calibration on the measurement device and to replace ageing components as needed.

Takeaway

Electrical measurement devices can be subject to a variety of errors that can affect the accuracy and reliability of their measurements. These errors include reading errors, range errors, zero errors, systematic errors, random errors, hysteresis errors, interference errors, and drift errors. To minimize the impact of these errors, it's important to select the appropriate measurement device, calibrate it regularly, and take measures to ensure proper training for your operators staff.

The training should be at least once per year and include the basics for personal safety.

Our experienced team is dedicated to providing you with the solutions you need to ensure accurate and reliable energy measurements. Whether you're looking for guidance on selecting the right equipment or need help with on-site testing and calibration, we're here to help. Contact us today to learn more!

Editor's note: This article was originally published in April 2023 and has been updated for comprehensiveness.

All comments are moderated before being published. Inappropriate or off-topic comments may not be approved.