In order to protect the utility revenue it's essential to do regular on-site tests on meter installations. If you are suffering huge losses Technical vs Non-Technical Losses: What You Need to Know you should focus on transformer operated meters first.

Technical vs Non-Technical Losses: What You Need to Know you should focus on transformer operated meters first.

Those meter installations can be faulty at different points:

- the instrument transformer ratio does not match with the meter

typical mistake is a wrong programmed meter

the fault can be figured out by checking the meter accuracy on the primary side - the burden of the instrument transformer does not match with the installation

typical mistakes are:

– wiring is too long or wrong cross section

– a backup meter is installed and overburdens the installation

the fault can be figured out by doing a burden measurement - the instrument transformers have a ratio- or phase displacement error

the fault can be figured out by doing a instrument transformer test - The meter accuracy is out of range

Old electromechanical meters (ferraris meters) have worn-out uper and lower bearings. If you hear a scratching sound coming from the rotating disc it's likely possible that the meter is running too slow. - wrong installation (tamper or mistake of the installer)

This is the part I saw most often. Let's take a closer look on this.

Wrong Installation

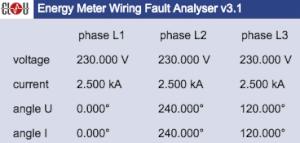

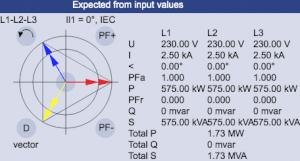

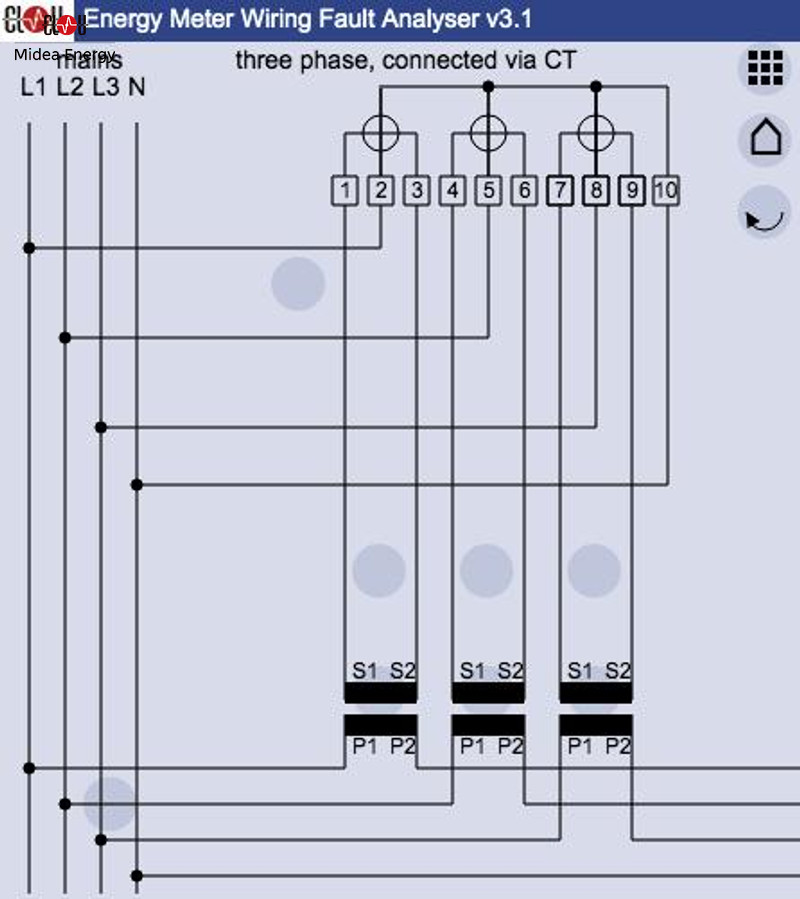

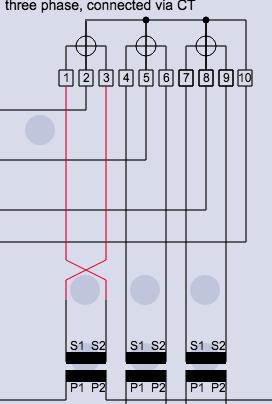

In our example we have a three-phase four wire CT-operated meter 2500/5 A, like it's installed in shopping malls and for small industry. We assume that the consumption is equal to the nominal load.

The wiring looks like this:

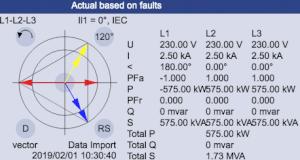

What happens when by mistake an instrument transformer for one phase is reversed?

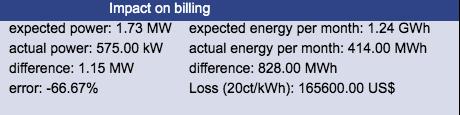

We see that this simple mistake is causing a loss of 66%. Or in terms of money 165,600US$ per month. (20ct/kWh)

In Germany the utilities are inspecting CT installations every 6 months. CT/PT installations are inspected every 3 months.

Conclusion

The real loss reduction does mainly comes mainly from good maintenance of the transformer operated metering installations.

What is your experience with on-site test of energy meters? Leave us a comment below or use our contact form Contact Us. Thank you for reading.

Contact Us. Thank you for reading.

Editor's note: This article was originally published in October 2019 and has been updated for comprehensiveness.

A very important article. Congratulations. Once in a gas generation plant ( 170 MW) we detected a problem with the connection with the rev meters, were around over 20% negative. Also as manufacturer of Combined CT&PT up to 33 KV, this is a typical problem. I don't know if you know, most rev meters for high consumers meter have problems with GPS clock. Big problem, because also they were sold for Power Quality.

Thanks, Mariano. You are right. Problems with the clock can lead to extreme losses.

شركة Clou أرسلت لنا جهاز جديد لفحص العدادات الالكترونيه نوع CL30005

Thanks for your comment. It's a nice test system for stationary meter test.

hi am having a problem with top up

of token

This can have several reasons. The easiest way is to contact your power supply company.

Hello, nice post here. How does one reconfigure a meter? I want it to bear a different meter number

Thanks for the comment. Meter numbers are assigned to the meter for lifetime and can't be changed.

That's very informative. Thanks for sharing.

Thank you for reading.