In customer requests and tenders you can still find extensive requirements for the stability of the output settings.

But, what does a stability requirement "< 100 ppm, Ti = 120 s" really mean? Let's take a look at a real world example taken from our test bench type CL3000.

To make a real stability test you need an external reference standard, minimum with the same accuracy as the internal reference, e.g. class 0.02.

You set the reference standard integration time to your required Ti. Typically, the test bench manufacturers are indicating a Ti of 100 seconds or 120 seconds. The 100 seconds Ti is more difficult to meet than the 120 s Ti. We will see the reason later.

Then you set your test values (voltages, currents, power factors, frequency) and start the recording of the external reference standard. A pre-warmed power source will give you better results.

The reference standard records for every Ti period the mean-value over the period. So with an integration time of 120 s we will have after the test 30 records.

The real minimum run-time for the test is one hour plus Ti.

After the run time is finished, the external reference standard evaluates the stability based on the minimum and maximum values.

Real example from voltage amplifier CL309-U

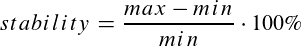

I did recently some evaluations for other purpose, but we can take the record set for better understanding of source behaviour and stability tests.

The record set consists of actual values, taken every 5 seconds from the internal reference standard. We have in total 720 samples. Setting value was 230 V. The source was not pre-warmed.

Looks pretty much scary, but it isn't. The voltage amplifiers have an internal stabilizer. This is the cause for the frequent change in amplitude. We can also see that the drift is going in plus direction.

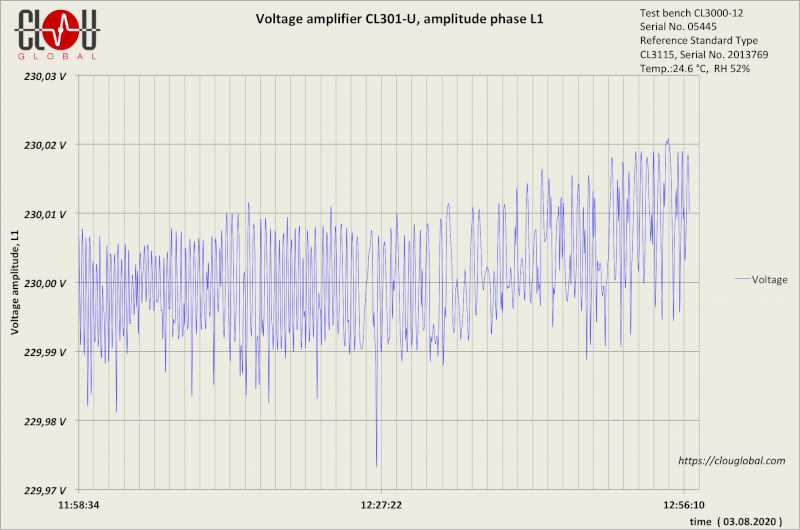

The same diagram with the allowed error limits

The voltage output is perfect within the 200 ppm limits for one hour without any regulation from the reference standard. The amplifier stabilizes itself.

What about the drift?

We can see that the voltage is slightly increasing. In the above record set we reach +100 ppm after one hour. At this point the amplifier measurement module decreases the voltage by 100 ppm, and we return to the 230.00 V. (Simplified and related to the module calibration done by the internal reference standard.)

During the whole run time the reference standard is reading permanently the output value, but it doesn't take any action. The amplifier is self controlled.

In the unlikely event of a sudden burden change in the test circuit the reference standard is used to bring the test value to the required amplitude. Other companies are relying on the closed loop reference standard feedback. For us it's an additional fail-safe.

What about the stability?

Finally, we come back to the topic. For the above example we come to different values for the stability. A longer integration time gives a better stability measurement. Keep this in mind when you compare specifications.

Note: All results are calculated based on 5 seconds real time values. By taking a 5 seconds integration time the stability will be even better.

| Integration time Ti | stability (one hour) |

|---|---|

| 5 s | 209 ppm |

| 60 s | 87 ppm |

| 100 s | 69 ppm |

| 120 s | 64 ppm |

| 200 s | 62 ppm |

The diagram shows the allowed gap between the red and the green line for a 100 ppm stability.

Why are the test results much better than specified in our product description?

Our R&D is pretty much conservative in giving tight specifications. The above test was done with 230 V. We need to cover the whole range from 30 V to 456 V. This needs extensive testing on a lot of amplifier samples with different ranges and different loads.

So at least for now we stick to the given specifications, but we know very clear the capability of our power sources.

Final thoughts

In my humbled opinion the stability of a power source for meter test purpose is not important any more. Except, you do the meter test with watt meters and a stop watch.

The internal reference standard captures the test values on wave sampling base and the measurements are always within the reference standard accuracy.

The same principle applies for portable meter testing. Here you don't have any influence on the voltage fluctuation and load conditions.

Thank you for reading and "Happy Testing".

Editor's note: This article was originally published in August 2020 and has been updated for comprehensiveness.

All comments are moderated before being published. Inappropriate or off-topic comments may not be approved.