Another new test introduced by the IEC62052-11 Edition 2 is the repeatability test. Actually we as energy meter manufacturer are doing this always for new products in our own interest. A trustable, good repeatability is essential for volume production.

What is Repeatability?

It's the difference between the maximum measured percentage error value and the minimum measured percentage error value of a number of test results, where the tests have been performed under the same conditions of measurement, i.e.:

- By the same measurement procedure

- By the same observer

- With the same measuring instruments, used under the same conditions

- In the same laboratory

- At relatively short intervals of time

Which Tests are required?

| Current | Power factor |

|---|---|

| Imin | 1 |

| 0.1 In | 1 |

| 0.1 In | 0.5 |

| 0.1 In | 0.8 |

| In | 1 |

| In | 0.5 |

| In | 0.8 |

| Imax | 1 |

| Imax | 0.5 |

| Imax | 0.8 |

See IEC table 11 for other meter types

The lowest specified nominal voltage of the meter shall be used. The IEC requires at least 3 tests after the meter has reached its thermal stability.

The thermal stability in context with the repeatability is a bit fancy because the thermal stability test relies also on the error measurement. So I suggest doing a traditional pre-warming, e.g. two hours with the maximum Un and then follow the test plan in the table with 5 tests (4 repetitions). The test bench control software will make the evaluation and generates the report automatically.

By IEC definition the repeatability shall be ≤ ⅕ of the error limit. (Simplified, read the original wordings in section 7.8). If you don't have the new standard, you can buy it e.g. here. We get no commission :)

So, for an energy meter with accuracy class 1 the repeatability shall be better than 0.2%.

The main cause for poor repeatability

If the repeatability test fails you have most likely not taken enough pulses for your error calculation. Electronic energy meters tend to have a jitter effect which is equalized over a longer testing period.

We have made good experience with CLOU test benches, using a minimum test time of 10 seconds or two pulses (whatever applies earlier). The test bench control software is calculating the required number of pulses based on the time. It's a simple and very efficient method when you have to deal with plenty of different meter types.

If the repeatability test is still fail after you have doubled the testing time or the number of pulses, the problem is related to the meter. It will most likely never pass the type test.

Conclusion

The repeatability test gives you valuable information about the meter behavior. Note down the number of pulses or the test time for each test point. You will need it to gain trustable test results for all other type tests related to error measurements.

The test for influence of self heating relies pretty much on small repeatability.

For volume production, we have of coarse optimized the durations for the various accuracy tests. For you in the laboratory, a longer test time has less impact and gives an even more stable result.

Final thoughts

Without having a very narrow repeatability its impossible to run a volume meter production with narrow overall errors.

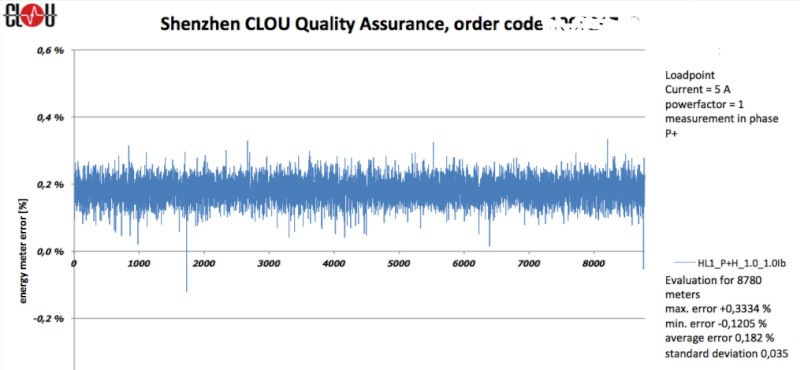

We are doing very comprehensive data analysis for our quality control and assurance. The graphics below is taken form a record set of a recent sampling (8000+ meters) during running production.

Our internal PASS/FAIL criteria for an accuracy class 1 meter is 40% of the allowed error value. This can only be achieved by doing extensive repeatability test first.

Of course, we can learn a lot more from this diagram, but this is worth some other blogs.

Thank you for reading and "Happy testing".

Editor's note: This article was originally published in July 2020 and has been updated for comprehensiveness.

It is a very important tests that must be showed to principal Utility customers, in order they can know about our quality. We have been in the revenue meters for a long time, we gave the tech & Comm support to AMETEX US for Latam ( Latin America markets for their rev meter JEMStar). Same for another US suppliers, and the most important for large users is about accuracy with the rev meters on site and working with “real” load. So, if you have this tests of above, please send it, because would demonstrate about accuracy with difference of volts of the grid, arise Temp, variation of the frequency Hz, and very bad with Harmonics, Flickers, etc., WHERE THE REV METERS ARE MEASURING AND THER IS MONEY TO PAY FOR THE BILL, so if accuracy moves, customers pay more, etc. I am sorry so long, but it is real world. Thanks.

Mariano, thanks for your comment. You've highlighted already some reasons for having energy meters type tested according to IEC. This type test is done by an independent laboratory and covers all aspects of environmental- and grid influences on meter behaviour and accuracy. IEC is in many terms stricter than the ANSI standard. We'll send you a comprehensive type test report for an energy meter for your reference.