Recently some new cases of COVID-19 infection came up in our region. To avoid spreading, the local government has implemented efficient mass test measures. It's still not like in the animation, but we come closer.

In our district, about 5 million people are tested within three days.

This requires proper planing, workforce management, material procurement and logistics.

For the stations 1 to 3 we have already last year an automated solution invented.

Station 4 is still human work, some test candidates feel uncomfortable.

Good thing, by now all screening results are negative.

Testing is always better than guessing.

Speed up your Meter Tests

Testing of energy meters takes time, because you need to follow certain procedures. Since all reputed meter manufacturers are testing their products after final assembling as part of the production process, power companies and utilities are doing typically a test on sample base. The sample quantity is internationally not fixed, most countries are taking a random 4 % sample, while for example Germany sticks on testing 20 %.

The manufacturers are providing the test results. So you can use them for comparison and for adjustment of the sampling rate.

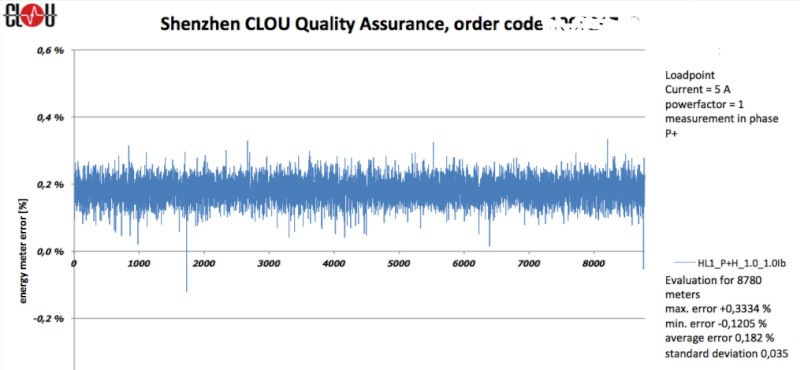

In the diagram taken from production, we see the typical error distribution for an energy meter class 1. By internal company rules no meter is leaving the production site when the error exceeds ±0.4 % (class 1, Ib, PF 1).

Compare with your supplier (and let me know the result).

Energy Meter Procurement

It doesn't matter, where you source your energy meters. Take care about a high meter constant.

The test procedure becomes much shorter, especially for no-load test, starting test and meter constant test.

A high resolution for the energy register is also recommended. To be efficient for the register/meter constant test, we need high constants and high register resolutions.

Meter Batch Selection

Equip the test bench always with meters having the same meter constant. Otherwise, the whole test run is hold-up by the meter with the lowest constant. Especially for no-load and starting test, you can easily save half an hour.

Review Your Test Plans

If you are still using manual transformer test benches, send me a photo. I haven't seen one for a while. Modern meter test benches are computer-controlled. There is a test plan or a test sequences for each meter type or family.

Review the test plans and compare with the standards. Maybe you find unnecessary items.

The test plans are all working with a time-out. Means, the test bench software is calculating the run-time and adds a certain percentage on top. If a meter is too slow or the scanning head is not good adjusted, the test bench continues with the next step after the time-out.

This meter is evaluated as "not tested".

The typical time-out setting is 115 %. Actually, it can be set to 105 % since it's useless waiting time.

For special research, you also can raise the timeout.

Don't try to fix something during the running process unless you know what you are doing. Collect the "not tested" meters for a new test run.

Scanning Head Adjustment

Avoid sunshine in the testing area. It can disturb the scanning head functionality. This is not only for CLOU, it's a general problem for all test benches.

Adjust the scanning heads before the test run on maximum load. Then you can be sure that the meters are well-connected, and the scanning heads are operating normal.

Otherwise, you will discover a problem after the starting-test. Since the no-load test will be PASS, you are losing about one hour.

Automation in Meter Testing

In China, with the world's largest smart meter installations, still 100 % of all ordered meters are retested with the test procedure given in IEC 62058-31. Due to the very huge volume of meters, it is necessary to have a full automated test setup.

CLOU has already delivered testing automation for over 20 test centres. The maximum capacity for single phase meters is 1,200 pcs/h.

If you have to test huge quantities of energy meters, talk to us. Our competent sales team will find the optimum solution.

Since you have read the article up to this point, maybe you'd like to share your approach for reducing test time with our readers.

Thank you for taking a look, and stay safe!

Editor's note: This article was originally published in June 2021 and has been updated for comprehensiveness.

very helpful, thanks for sharing.

Thank you for taking a look.